Bearings

Our ball bearings range at Engineers Mate has been carefully selected for exceptional performance and durability and our premium range of bearings is available to ordered 24/7 at wholesale prices.

We only work with leading brands such as NTN and FAG to ensure you receive bearings that are built to handle all demands of your machinery and application.

We are your go-to partner for keeping things moving smoothly, providing quick turnaround times and expert assistance.

Ball Bearings Supplier

Bearings – More Than Just Components

Bearings are essential machine components designed to guide motion and minimise friction, allowing smooth rotation, linear travel, or controlled movement across multiple axes.

Choosing the right bearing, whether ball, roller, linear, fluid, magnetic, or plain is crucial to ensuring the efficiency, durability, and reliability of any engineering system.

Why Choose Engineers Mate Bearings?

Superior Performance & Durability: Engineered to excel in demanding conditions with trusted brands like NTN and FAG for unparalleled quality.

Wide Variety & Versatility: Extensive inventory from ball, roller, and needle bearings to linear and spherical types, covering a broad range of industrial applications.

Expert Guidance: Specialized support to match bearing selection with application needs taking into account speed, environmental conditions, dimensions, material, and load capacity.

Fast UK Delivery: Centrally based in the UK, offering efficient service tailored to your schedule.

Types of Bearings & Applications

| Bearing Type | Features & Uses |

|---|---|

| Ball Bearings | Ideal for high-speed, low-friction applications; handle both radial and light axial loads. |

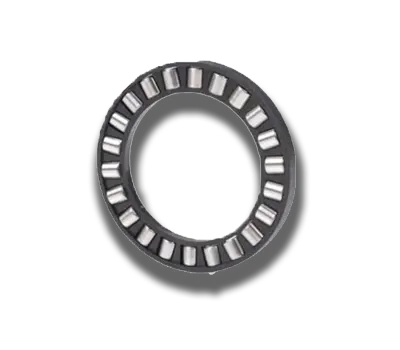

| Roller Bearings | Support heavy radial loads; available in cylindrical, tapered, spherical, and needle designs. |

| Needle Roller Bearings | Slim profile with high load capacity; excellent where space is limited (e.g., automotive, power tools). |

| Tapered Roller Bearings | Handle combined radial and axial loads; common in wheel hubs, transmissions, and heavy machinery. |

| Spherical Roller Bearings | Accommodate misalignment; suited to high radial and axial loads in industrial environments. |

| Plain / Journal Bearings | Simple, cost-effective design; perform well when properly lubricated. |

| Fluid Bearings | Near-zero friction via a pressurised fluid film; ideal for high-speed, precision systems such as turbines and hard drives. |

| Magnetic Bearings | Non-contact support using magnetic fields; low friction and minimal maintenance for high-precision environments. |

| Linear Bearings | Enable smooth linear motion in robotics, CNC machines, and automation; available in ball or plain formats. |

How to Choose the Right Bearing

Selecting the correct bearing for your application depends on several key factors:

Type of Load

- Radial Loads: Best handled by deep-groove ball bearings or cylindrical roller bearings.

- Axial (Thrust) Loads: Suited to thrust ball bearings or tapered roller bearings.

- Combined Radial & Axial Loads: Angular contact, tapered, or spherical roller bearings are most effective.

Bearing Speed Requirements

Ball bearings are ideal for high rotational speeds thanks to their low friction. Roller bearings, while more robust, are generally better suited to slower applications with heavier loads.

Environmental Conditions

Operating conditions such as high temperatures, dust, or exposure to moisture play a major role in bearing selection. Stainless steel, ceramic, or coated bearings may be required for corrosion resistance or specialised environments.

Dimensional Compatibility

Bearings must match the inner diameter, outer diameter, and width of the shaft and housing to ensure correct fit and performance.

Material & Precision

The precision rating (e.g., ABEC scale) indicates tolerance levels. Higher classes provide smoother operation and are essential in high-speed, high-precision systems.

Misalignment Compensation

Where shaft and housing alignment cannot be guaranteed, spherical or self-aligning bearings are recommended.

Maintenance & Lifetime

Sealed bearings require minimal upkeep and are suitable for hard-to-reach installations. Open bearings, fluid, or magnetic designs may offer long service lives but may need tailored maintenance and lubrication strategies.

Bearing FAQs

- What’s the difference between radial and axial loads?

Radial loads act perpendicular to the shaft axis, while axial (or thrust) loads act parallel to the shaft. - When should I choose tapered vs. spherical roller bearings?

Tapered roller bearings are best where both axial and radial load support is needed, such as in vehicle hubs.

Spherical roller bearings are the right choice when misalignment is likely and heavy loads must be supported. - What are the benefits and drawbacks of fluid bearings?

Benefits: Extremely low friction, high precision, long service life, and quiet operation.

Drawbacks: Potential wear during startup/shutdown and the need for a controlled fluid supply system. - What is the ABEC scale and why does it matter?

The ABEC scale classifies bearing precision, from ABEC 1 up to ABEC 9. Higher ratings mean tighter tolerances, smoother operation, and suitability for high-speed or precision applications. - Are magnetic bearings worth it?

Yes—magnetic bearings are excellent for applications that demand non-contact operation, zero mechanical wear, and very high precision or cleanliness. - How do environmental factors affect bearing choice?

Operating temperature, exposure to dust or moisture, and chemical conditions all influence bearing performance. Materials such as stainless steel or

coated bearings can improve corrosion resistance in harsh environments. - What maintenance is required for bearings?

Sealed bearings require little or no maintenance and are ideal where access is difficult.

Open bearings need regular lubrication and cleaning. In abrasive or dirty environments, frequent grease replacement helps prevent wear. - Can needle roller bearings replace ball bearings?

Yes, in many cases. Needle bearings provide high load capacity in a compact design, making them suitable where radial space is restricted.