Comprehensive Gear Cutting & Manufacturing Solutions

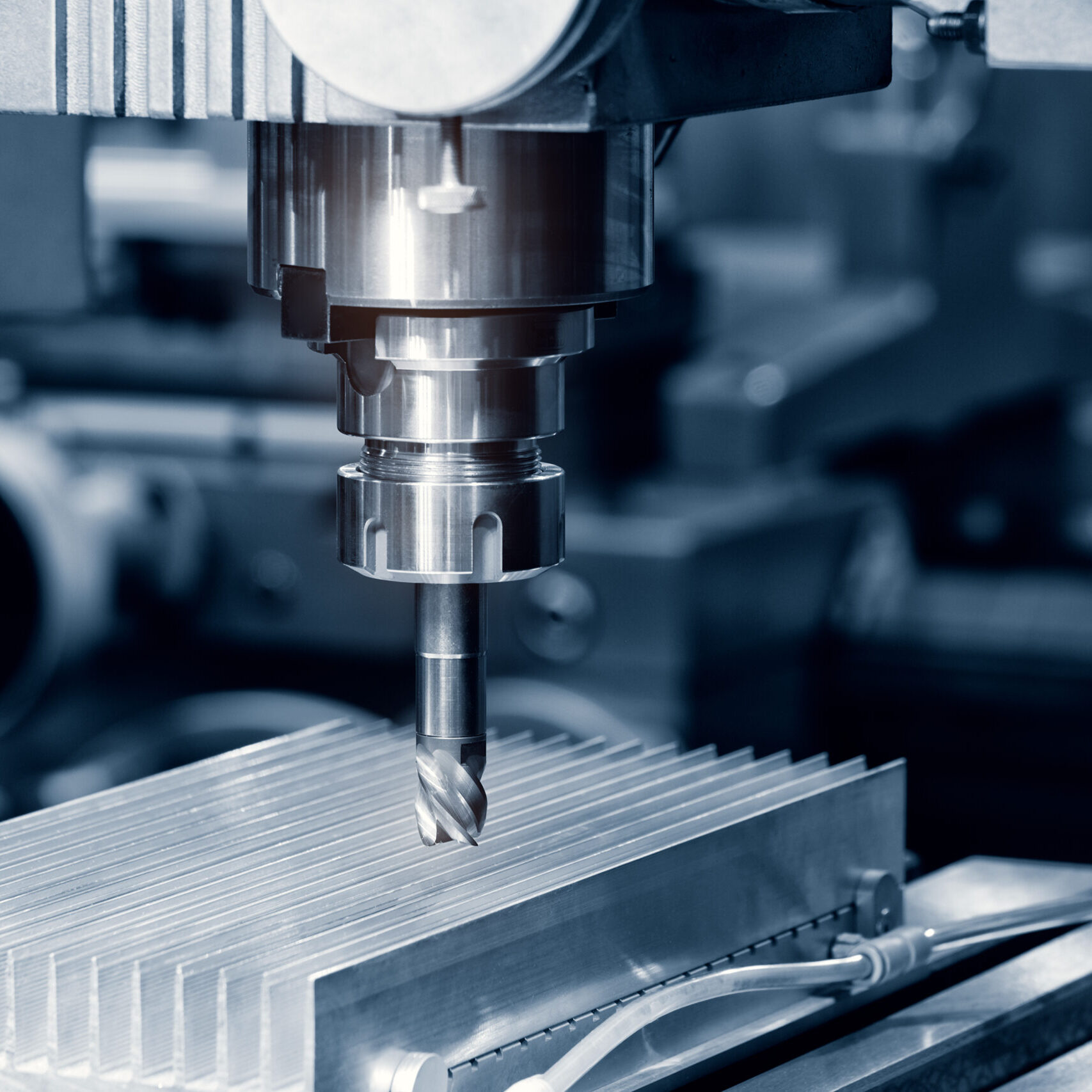

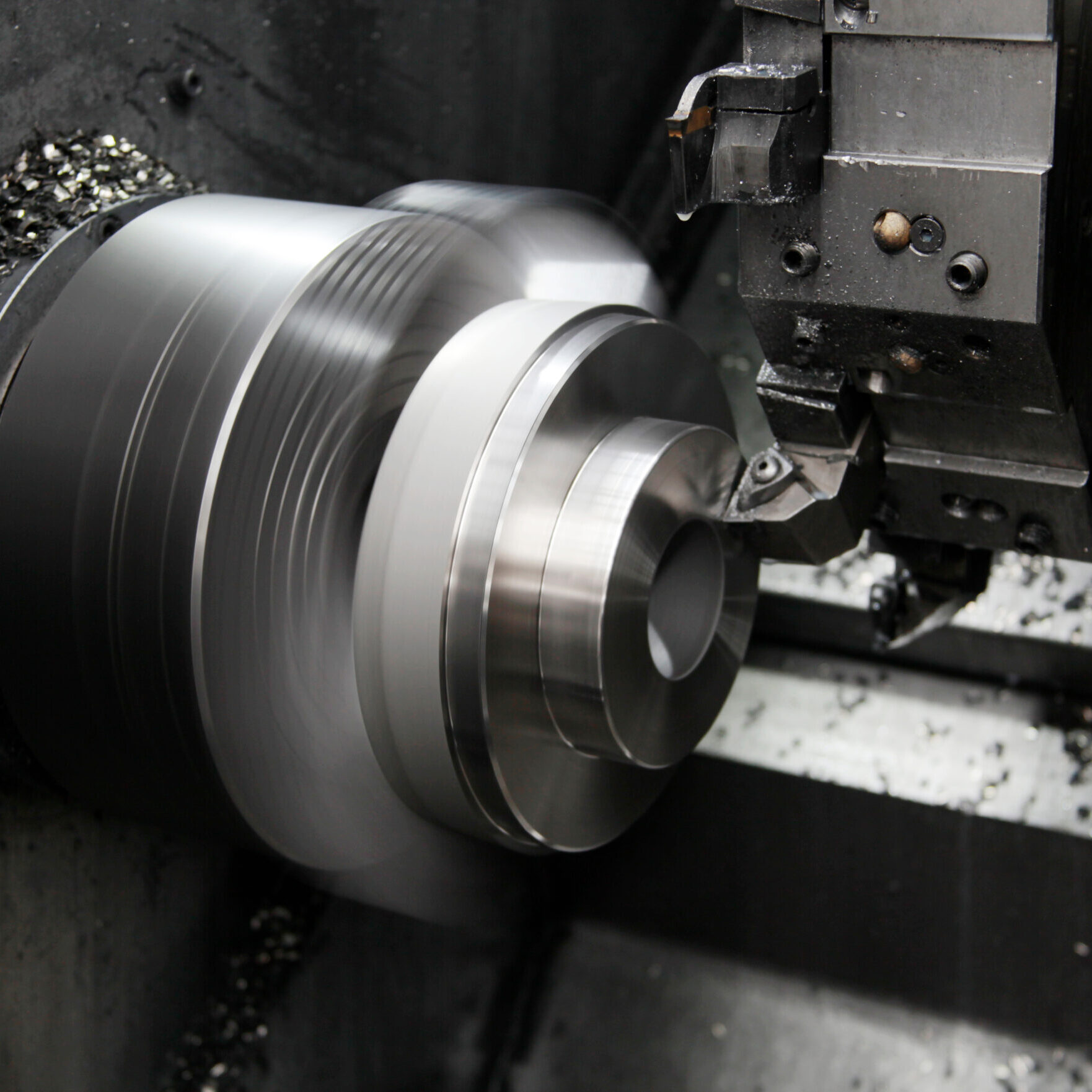

We utilise a variety of advanced manufacturing techniques to produce high-quality gears tailored to your specific needs. Our gear cutting & manufacturing methods include:

Key Benefits of Our Precision Gear Cutting & Manufacturing Service

Our gear cutting & manufacturing service plays a crucial role in various industries by ensuring the production of high-quality, reliable gears. Here’s how our round-the-clock support benefits your business:

Why Choose Engineers Mate For Gear Cutting & Manufacturing Service?

We work closely with customers to produce high-quality gears tailored to their exact specifications, using advanced machinery and skilled engineering. Whether it's one-off components or batch production, we ensure accuracy, fast lead times, and exceptional service throughout.

Here are just a few reasons why customers choose us for their gear cutting & manufacturing requirements:

Contact Us

For more information about our Gear Cutting & Manufacturing Service, or to discuss your specific requirements, contact Engineers Mate today. Our expert team is ready to help with tailored solutions that keep your operations running smoothly.

Call us on 01952 676925 to speak with one of our experienced engineers.

Get in Touch with Engineers Mate

At Engineers Mate, we’re committed to keeping your operations running smoothly. Whether you need a quick replacement for a critical breakdown or expert advice on improving your plant’s efficiency, our team is here to help.

From sourcing high-quality MRO supplies to offering tailored solutions that optimise performance, we’ll work closely with you to meet your unique needs. No matter the challenge, you can count on us to deliver peace of mind and reliable support.

Fill out the form, and a member of our team will be in touch shortly to assist you.